Dorlen Rubber & Urethanes

Custom Rubber & Polyurethane Manufacturing in Adelaide

Located in Lonsdale, South Australia, 25 km from the Adelaide CBD, Dorlen Rubber & Urethanes specialises in custom rubber manufacturing, polyurethane casting, rubber extrusion, and re-vulcanising for industrial, automotive and specialist applications.

Custom Rubber & Polyurethane Manufacturing in Adelaide

Committed!

Rubber & Urethane Experts Since 1977

Dorlen Rubber & Urethanes has been in the custom rubber & polyurethane manufacturing industry in Adelaide for 45 years. With decades of experience and in-house R&D, we deliver custom rubber moulding, polyurethane sheeting and casting, O-ring manufacture and full engine-mount recondition services tailored to your needs.We primarily work with rubber, polyurethanes, silicone & bonding these together or to metal; however, we also specialise in R&D and can develop moulds and dies to fit your specific needs. From large production runs, to small one off jobs we have the experience and capabilities to complete all your rubber & urethane projects.

Hours of Work

Projects Done

Client Satisfaction

Some of our incredible Clients

Why Choose Us

Quality Products

Professional Service

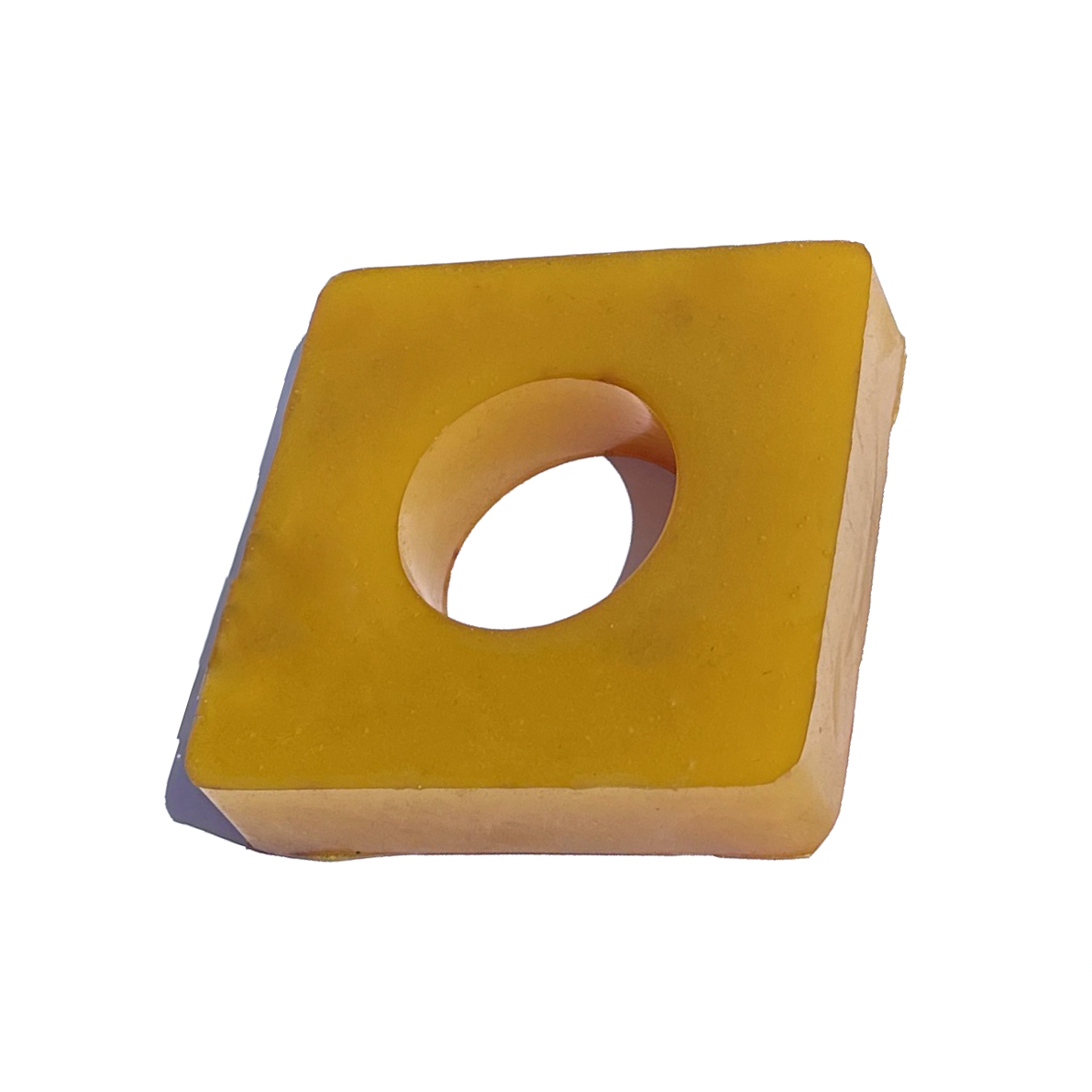

Polyurethane

Durable. Versatile. Engineered for performance.

Dorlen Rubber & Urethanes specialises in polyurethane moulding, casting and sheeting for demanding industrial and automotive applications. Our polyurethane compounds offer exceptional abrasion resistance, load-bearing strength, and chemical durability, outperforming conventional rubber in many cases.

We can cast polyurethane parts in any hardness (Shore A 40 – D 75), colour, and configuration — from bushings, rollers and wheels to impact pads, seals and custom components.

Whether you need urethane sheeting, custom-moulded polyurethane parts, or urethane bonded to metal, we tailor every batch to your specification.

Contact our Adelaide team for a quote on our custom polyurethane molding services.

Silicone

Precision performance for high-temperature and food-grade applications.

We manufacture custom silicone mouldings and extrusions for applications where flexibility, hygiene, or temperature resistance is critical. Dorlen’s silicone products are ideal for medical, food processing, laboratory, and electrical sealing environments.

Our silicone compounds can withstand temperatures up to 250 °C, remain flexible in sub-zero conditions, and meet FDA-compliant standards where required. We offer solid silicone, available in transparent, coloured or pigmented forms to match your specification.

Ask us about high-temperature silicone moulding or custom silicone extrusion today.

Custom Rubber & Polyurethane Manufacturing

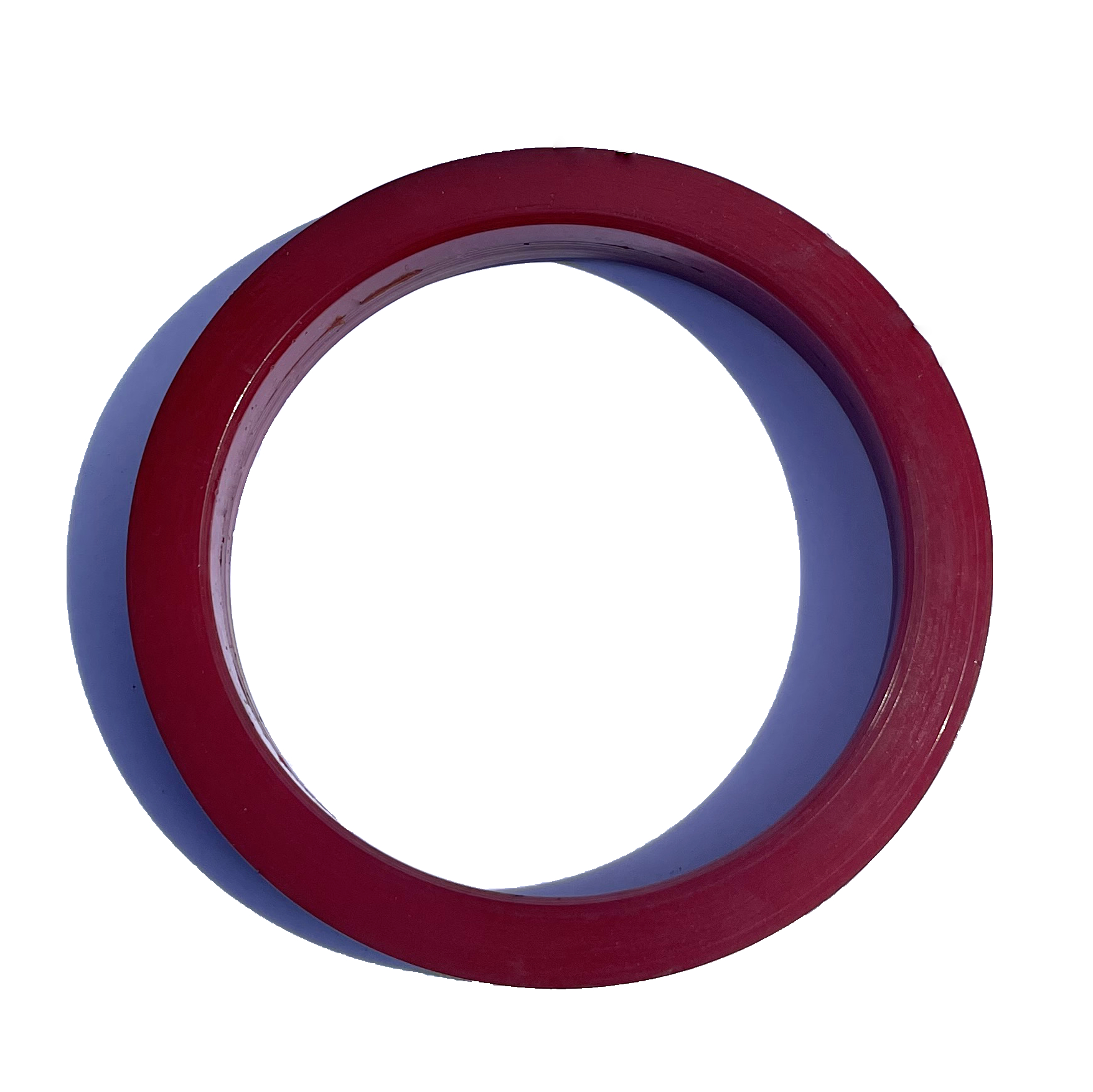

Rubber

Australian-made rubber components built to last.

Here at Dorlen Rubber & Urethanes, we produce and work with a range of natural and synthetic rubbers for industrial, automotive, and specialist applications. We stock Nitrile and EPDM rubber as standard to ensure quick turnaround on common jobs. Other compounds such as Butyl, Hypalon, Natural Rubber, Neoprene, and Viton are available on request — these are sourced specifically for your project and may involve additional lead times or minimum order requirements.

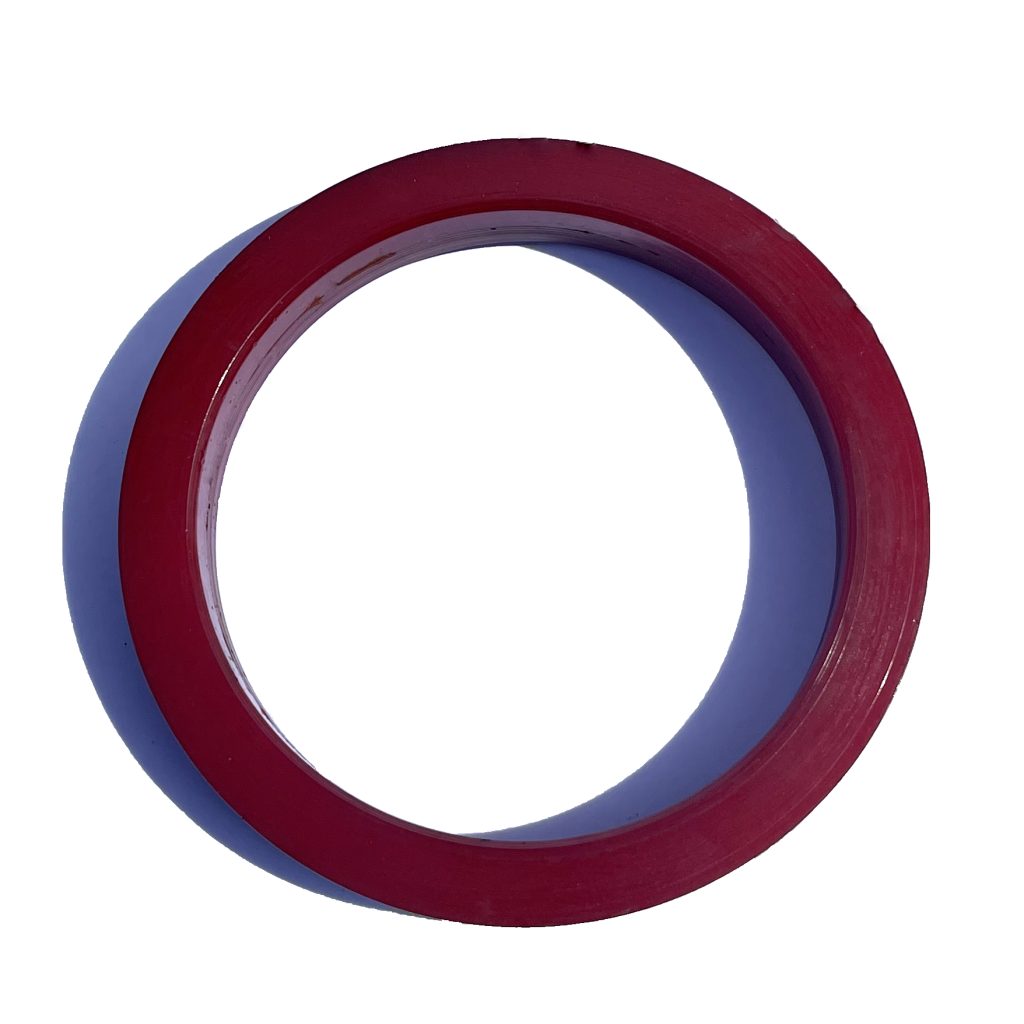

Our experienced team manufactures custom rubber mouldings, extrusions, and re-vulcanised parts for a wide range of uses — from engine mounts and seals to O-rings, gaskets, bushings and isolators. Using high-quality materials and precision tooling, we produce rubber products that withstand harsh environments, vibration, and heavy loads.

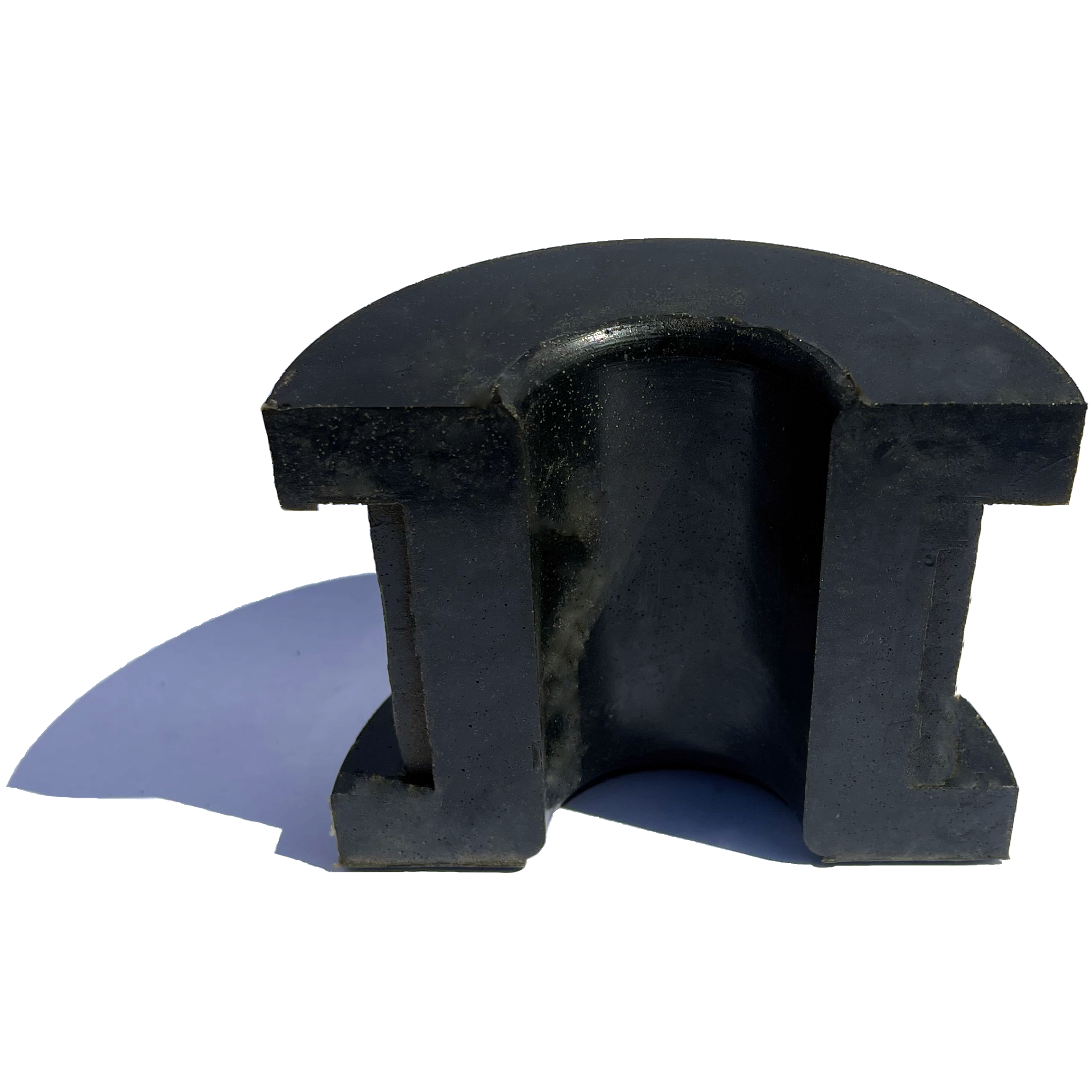

Bonding

Strong adhesion between rubber, metal and urethane.

Dorlen specialises in rubber-to-metal bonding and urethane-to-metal bonding, ensuring lasting adhesion under load, vibration and temperature extremes. Using advanced surface preparation and adhesive systems, we produce bonded mounts, rollers, bushes and isolators that perform where others fail.

Our team also provides re-bonding and re-vulcanising services to extend the life of existing parts, saving cost and reducing downtime across industries including mining, transport, and agriculture..

Talk to us about re-bonding or manufacturing custom bonded components for your next job.

Custom Rubber & Polyurethane Manufacturing

Rubber & Polyurethane Sheeting

Cut, cast and finished to your exact dimensions.

We produce rubber and polyurethane sheeting for impact protection, lining, gaskets and industrial wear applications. Sheets are available in a variety of thicknesses, hardness ratings and colours, designed to resist abrasion, oil, and chemical exposure.

Polyurethane sheeting is available in clear or pigmented finishes, ideal for cutting benches, press pads and protective surfaces. Rubber sheeting options include EPDM, Nitrile and Natural Rubber in roll or cut lengths.

Order custom rubber or polyurethane sheeting direct from our Lonsdale workshop.

Custom Rubber & Polyurethane Manufacturing

Rubber Extrusion

Continuous rubber profiles made to your exact specification.

Extrusion sends soft rubber through a shaped die to create long channels, tubing, cords, and seals in virtually unlimited lengths.

At Dorlen Rubber & Urethanes, our extrusions can be made in a wide range of colours, shapes, and composites, allowing precise control over flexibility, hardness, and appearance.

We manufacture custom extruded rubber profiles from compounds such as EPDM, Silicone, and Neoprene, ideal for door and window seals, O-rings, gaskets, irrigation tubing, weather stripping, and industrial hoses. Each extrusion is engineered for consistency, dimensional accuracy, and long-term durability — whether you need a one-off prototype or ongoing production.

Contact our Adelaide team to discuss your custom rubber extrusion profile or ongoing manufacturing requirements.

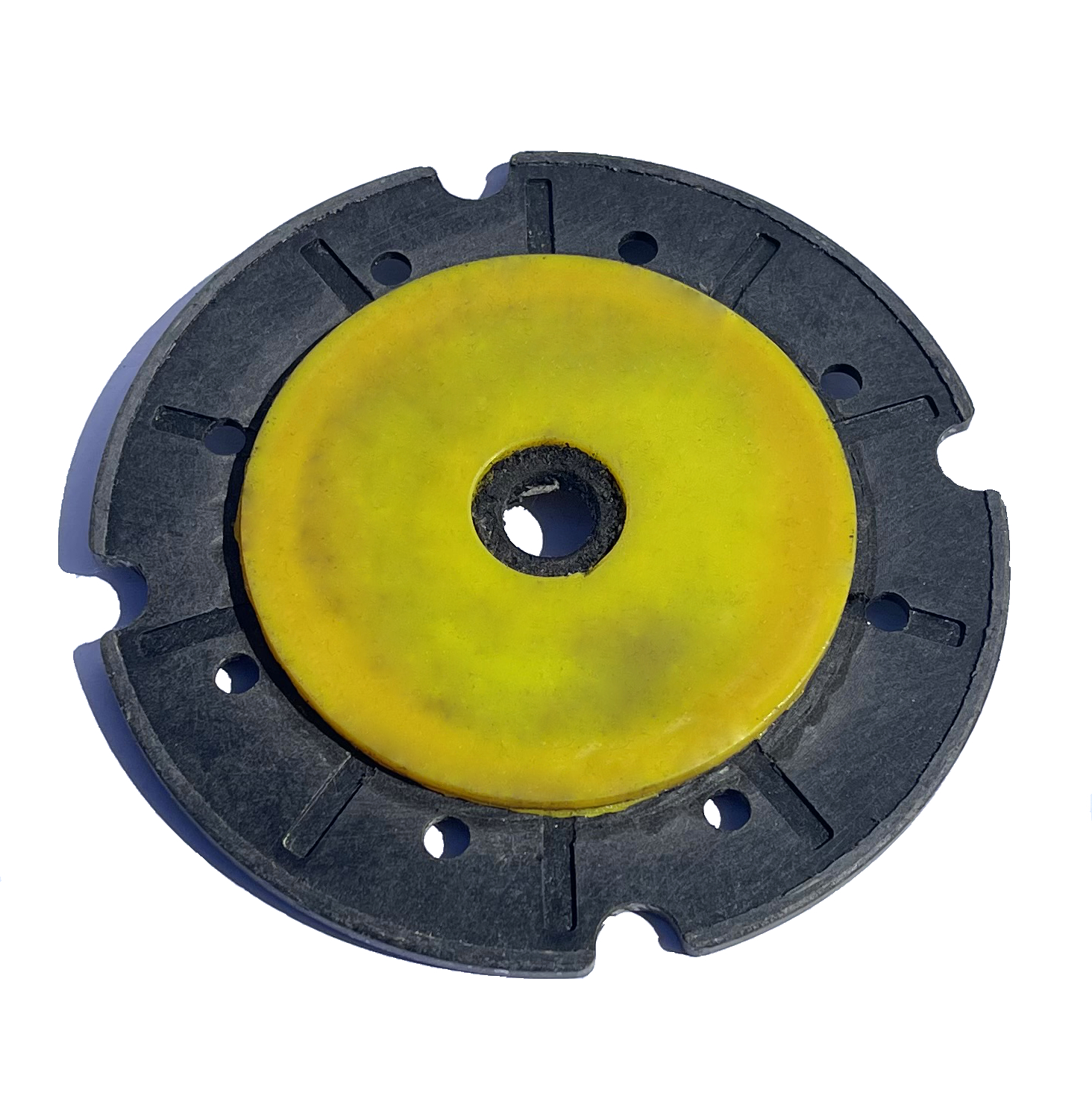

Compression Moulding

Precision moulding for small-batch and custom-shaped parts.

Here at Dorlen we can cater for all sizes of project whether you need 10 or 10,000 items. Compression moulding is a great way to create identical parts.

Our compression moulding process delivers durable, dimensionally stable rubber parts with smooth surfaces and consistent quality. It’s ideal for engine mounts, dampers, isolators, and gaskets.

We design and machine our mould tools locally, reducing lead times and ensuring tight control over quality and fit. Materials can include a range of natural rubber or synthetic compounds depending on application.

Need custom moulded parts? We can design, tool and mould to your exact requirements.

In-House R&D

Practical engineering and technical refinement — built on decades of experience.

At Dorlen Rubber & Urethanes, our In-House R&D focuses on improving performance, precision, and reliability through hands-on problem-solving. With over forty years of manufacturing experience, we help customers optimise part design, tooling, and production methods to achieve better results and longer service life.

Our technical team works closely with clients to: Review and improve existing rubber and polyurethane moulds for better accuracy or easier production; Prototype new components and confirm fit, hardness, and performance before full-scale manufacture; Diagnose field failures and recommend improved material choices or design adjustments; and Implement process and tooling improvements that shorten lead times and reduce waste.

Custom Rubber & Polyurethane Manufacturing

Request a Quote

Talk to an expert about your rubber and urethane needs today!

Custom Rubber & Polyurethane Manufacturing

Our Projects

Examples of our Work

Custom Rubber & Polyurethane Manufacturing

Our company is a collective of amazing people striving to build Durable, Useful products.

Dorlen Rubber & Urethanes was founded in 1977, by Doreen and Leonard Hill (DorLen) who had a fascination with the forms rubber could take. Through their 42 years running the business they developed a large range of rubber and urethane products and processes. Dorlen is now a leading custom rubber & polyurethane manufacturer in Adelaide and wider Australia with a wealth of knowledge and experience.

Here at Dorlen, we provide products for a wide range of applications including: aerospace, agriculture, dairy, automotive, construction, electronics, energy, food & beverage, heating, lighting, mass transit, medical, and solar. We aim to continue discovering and developing products and processes to cater to each client’s specific needs. We pride ourselves in using, wherever possible, quality Australian master-batch and other local components to ensure we manufacture a consistently high quality product and support Aussies and the local economy.

Contact us for your Custom Rubber & Polyurethane Manufacturing needs today!